Herolaser robot laser welding system consists of fiber laser, laser power supply, control system, laser indicating positioning system, WOBBLE laser welding head, cooling system, etc. The laser generator adopts a fiber laser, the laser pulse waveform can be edited arbitrarily, and the energy output is stable.

The laser welding head adopts the laser welding head independently developed by Herolaser, which has very high welding stability and flexibility, and can be rotated 360 degrees.

The cooling system of the fiber laser welding machine is composed of temperature measuring device, water circulation, radiator and deionized resin.

The temperature measuring device detects the water temperature in the water tank in real time and judges whether the water temperature is too high.

If the temperature exceeds the upper limit, the system will automatically turn off the laser to avoid damage to the laser.

After the machine is turned on, the water circulation and the radiator form heat exchange with the outside world, which quickly removes the heat generated when the laser is working, ensuring that the laser is working properly.

The cooling system and the whole machine adopt an integrated design to make the system more concise and occupy a smaller area.

Angle welding of various complex products

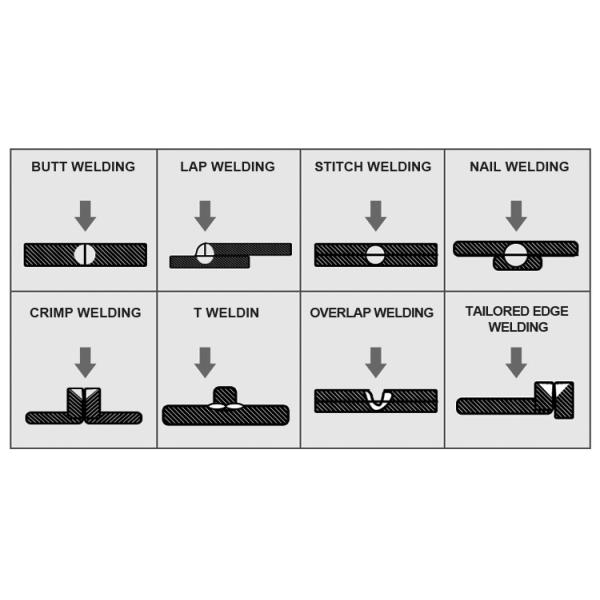

It can carry out flexible transmission and non-contact welding for difficult-to-access precision parts, which has great flexibility Adapt to the welding seam, tailor welding, butt welding and stitch welding of various complex products

Wobble Welding Head

Wider applications, large workpieces, workpieces with wider welding seams can be welded

Advantages of wobble welding machine technology

1. High quality spot welding

2. The allowable range of weld width is expanded

3.Beautiful weld

4. Can weld a variety of metals

5. Low laser power requirement 6. Process stability